歡迎訪問鶴壁市大圓碳素網站!

在線留言

在線留言

在線留言

在線留言

公司頭條:

服務熱線:

- 01 -

- 02 -

- 03 -

- 04 -

- 05 -

- 06 -

- 07 -

10-16

2019

客戶公司對浙江石墨電極掉爐料產品有大量的需求,而如今市場競爭激烈,選購質量尤為重要,在朋友的推薦下,選擇了我們鶴壁市大圓碳素公司的石墨電極掉爐料產品,驚喜的發現,我們提供的產品不但質量好,服務態度也是...

客戶公司對浙江石墨電極掉爐料產品有大量的需求,而如今市場競爭激烈,選購質量尤為重要,在朋友的推薦下,選擇了我們鶴壁市大圓碳素公司的石墨電極掉爐料產品,驚喜的發現,我們提供的產品不但質量好,服務態度也是...

10-16

2019

10-16

2019

客戶在選購浙江石墨顆粒產品的時候,特別迷茫,通過各種渠道,.終選擇了我們鶴壁市大圓碳素公司的產品,我們所提供的產品,都是經過嚴格把關,因此用起來特別得心應手,好的產品,好的服務,值得大家選擇,不容錯過...

客戶在選購浙江石墨顆粒產品的時候,特別迷茫,通過各種渠道,.終選擇了我們鶴壁市大圓碳素公司的產品,我們所提供的產品,都是經過嚴格把關,因此用起來特別得心應手,好的產品,好的服務,值得大家選擇,不容錯過...

10-16

2019

經驗深厚

方案專業

原料廠家

價格更低

經驗豐富

生產力強

貼心服務

無憂售后

對國內53家冶煉廠(涉及產能646萬噸)產量統計結果顯示,2022年1-2月樣本企業鋅及鋅合金產量為93.3萬噸,同比增加4.7%。2月份單月產量為47.4萬噸,同比增加8.3%,環比增加1.4萬噸,日均產量環比增加14.1%。修正后的2023年1月份樣本總產量為46.0萬噸,同比增加1.3%。2月份,春節假期結束,以...

單位:元/kg---------------------------------------------------------------------------------產品名稱 規格 標準 市場 *低價&...

Whitehorse Gold Corp.已將其名稱改為Tincorp Metals Inc.,反映出他們的(業務)重點向其玻利維亞的新的錫項目的"關鍵性轉變"。正如他們以前的名字所示,公司過去的重點是北美的黃金。然而,在建立了一支在玻利維亞頗有成效的團隊后,玻利維亞錫礦成為了該公司的新重點。Tin...

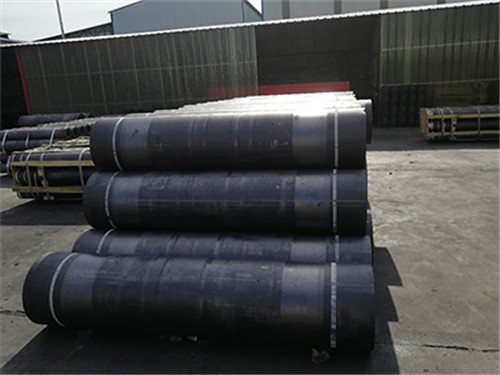

鶴壁市大圓碳素有限公司是一家從事石墨制品銷售及石墨制品制造的公司。公司成立于 2010 年 11 月 08 日,法定代表人李瑞,注冊資本為 1000 萬元人民幣,國家企業信用信息公示信用代碼/稅號:91410602563748899K,公司稅務登記 A 級。 公司地址:河南省鶴壁市鶴壁市經濟技術開發區甌江路 7 號,企業的經營范圍為:石墨及碳素制品制造;石墨及碳素制品銷售;新材料技術研發;新材料技術推廣服務;合成材料制造(不含危險化學品);合成材料銷售;金屬加工機械制造…

石墨是碳元素的一種同素異形體,也是一類重要的無機非金屬材料,為黑灰色不透明固體、有金屬光澤、質軟、有滑膩感,化學性質穩定,耐腐蝕,同酸、堿等藥劑不易發生反應。在氧氣中燃燒生成二氧化碳,可被強氧化劑如濃硝酸、高錳酸鉀等氧化,可分為天然石墨和人造石墨。石墨質軟,為黑灰色,有油膩感,可污染紙張。在隔絕氧氣條件下,其熔點在30...

電弧爐煉鋼是以廢鋼為主要原料,以三相交流電作為電源,利用電流通過石墨電極與金屬物料之間產生的電弧高溫來加熱、融化爐料以產生特殊鋼和高合金鋼的主要方法。而石墨電極作為電爐煉鋼的導電電極,對煉鋼的穩定運行起著支撐性的重要作用。浙江石墨電極小編為您科普一下。通常來說,電極在煉鋼過程的消耗中可以分為氧化、升華、溶解、剝落、折斷...

石墨塊供應商的石墨新材料是現代工業技術發展不可缺少的功能性基礎材料,素有“黑金子”美稱。鉛筆芯、手機鋰離子電池……,無不是石墨這種新材料界的“寵兒”制作而成。接下來浙江石墨顆粒小編就帶大家一起來了解下石墨塊的未來市場前景。 1、資源優勢得天獨厚,產業初具規模 石墨材料供應商據了解,石墨資源蘊藏豐...